Categories Liquid & Gas Analysis, Chemical

Process refractometer DCM-20 with industrial process connections for heavy-duty process control

Brand : KXS

Categories Liquid & Gas Analysis, Chemical

Process refractometer DCM-20 with industrial process connections for heavy-duty process control

Brand : KXS

The constant need for innovation and better process optimization solutions in the chemical industry is challenging. Factors such as sustainability, regulations, feedstock, energy costs, and technological advancements all need to be considered. At KxS, we design our products and applications with a deep understanding of these complexities.

Our process refractometers provide precise measurements to help you to improve product quality, increase efficiency, and reduce downtime.

By collaborating closely with our customers, we have developed solutions that provide the best value in the industry. Our refractometers are designed to withstand corrosive and abrasive conditions, extreme temperatures and pressures, vibration, contamination, humidity, dust, and any combination of these factors.

Whether you're dealing with chemical processing, heavy industry, or any application requiring high precision under industrial or extreme conditions, the KxS process refractometer is your trusted solution.

We’re here to assist you with your process monitoring needs—offering support at every stage. From expert application consultation and selecting the right solution to smooth startup and support over the lifecycle.

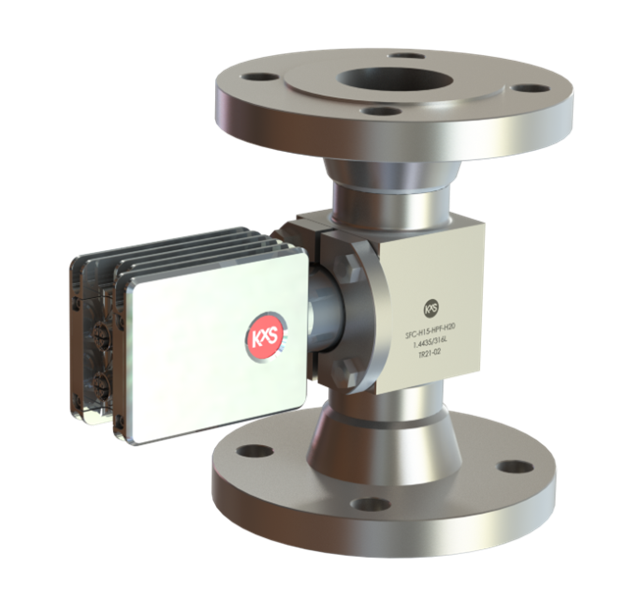

KxS process refractometer DCM-20 is intended for reliable liquid concentration and density measurements in wide range of chemical and industrial process applications. It is installed in the main processing line, bypass line or vessel either directly with industrial Flange or L-coupling process connection, or via flow cell or pipe section.

The DCM-20 withstands corrosive and abrasive conditions, extreme temperatures and pressures, vibration, contamination, humidity, dust, and any combination of these factors.

It is true stand-alone device with all measurement functions integrated in the sensor, thus eliminating the need of transmitter. Measurement output options include both analog and digital communication protocols. Two cable connection ports offer dual analog 4-20mA and Modbus TCP.

For enhanced functionality, an optional HMI unit offers a local display and interface, ensuring user-friendly operation.

In demanding process conditions, one mA-output can be dedicated to controlling the optical window wash, maintaining optimal performance and cleanliness.

When standard model codes are not sufficient to fulfill requirements, please consult the factory for engineered solutions, e.g. special wetted materials or custom process connections. The engineered solutions may be subject to additional delivery time.